Energy Management & Leakage Detection

"What would you say if we found out that you could save several thousand euros a year in energy costs?"

- Leaks are a permanent waste of energy!

- No expensive investments necessary!

- Simply reduce production costs!

- Environmental protection and economic efficiency included!

Compressed air circuits enable an enormous amount of energy savings

without costly investments with direct benefits. Because compressed air is the most widely used

and at the same time the most expensive energy fluid in the industry, it lies as energy cost factor

of a company is often on the second or third rank of production costs:

- 75 % Energy supply*

- 13 % Capital expenditure

- 12 % Maintenance costs (*for consumption over 5 years with 6000 operating hours per year)

Potential for improvement:

1. to reconcile the actual requirements of production and pressure level

2. reduction of energy losses/leakage elimination

3. maintenance of the components

4. checking the quality of the compressed air

5. avoidance of leakages in the network

Possible leakage locations:

line connections, drain valves, filters, pressure regulators, valves, quick couplings, rubber hoses

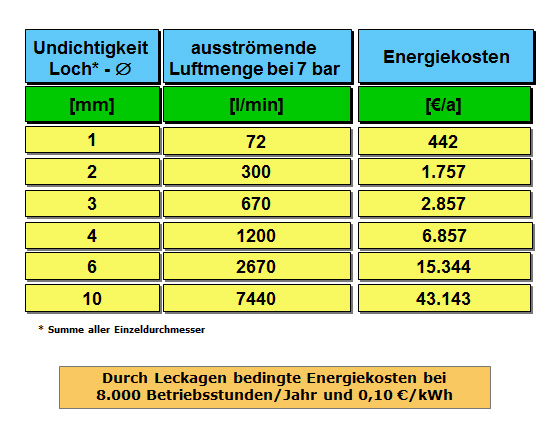

Determination of costs due to leakage:

A single leakage of 1mm at 7 bar pressure costs 422,00 Euro per year,

at 4mm this leakage already costs 6857,00 Euro... many underestimate these costs!

Realistic target:

A reduction of leakages in the compressed air circuit to 5% of the volume consumed

without costly investments with direct benefits. Because compressed air is the most widely used

and at the same time the most expensive energy fluid in the industry, it lies as energy cost factor

of a company is often on the second or third rank of production costs:

- 75 % Energy supply*

- 13 % Capital expenditure

- 12 % Maintenance costs (*for consumption over 5 years with 6000 operating hours per year)

Potential for improvement:

1. to reconcile the actual requirements of production and pressure level

2. reduction of energy losses/leakage elimination

3. maintenance of the components

4. checking the quality of the compressed air

5. avoidance of leakages in the network

Possible leakage locations:

line connections, drain valves, filters, pressure regulators, valves, quick couplings, rubber hoses

Determination of costs due to leakage:

A single leakage of 1mm at 7 bar pressure costs 422,00 Euro per year,

at 4mm this leakage already costs 6857,00 Euro... many underestimate these costs!

Realistic target:

A reduction of leakages in the compressed air circuit to 5% of the volume consumed

Annual energy costs due to undetected leakage